ULTRA SURFACE MATERIAL

ULTRA SURFACE is a brand new “Hybrid Quartz” material, which is composed of selected quartz and highly purified fine rock crystal, unique resin matrix, and special reinforcing fibers.

The distinctive feature of ULTRA SURFACE is its super hardness (pencil hardness 8H). Therefore, it is hard to scratch by daily life activities. The high hardness property of Ultra Surface makes it possible to create dark colors lineups, which is hard to achieve with regular composite materials because of the easy scratch issue. Moreover, it has the highest impact resistance property. According to the steel ball drop test, Ultra Surface’s impact resistance property is several times higher than natural stones, ceramic plates, engineer stones (ES), and crystallized glass plates.

In addition, while quartz contained engineered stone (ES) is weak against alkaline, Ultra Surface is super strong against various chemicals such as alcohol, alkaline, and bleach. Yoshimoto’s unique composite material technology has corrected the weakness of compounding materials.

Due to the spread of the coronavirus, the use of alcohol disinfectants is increasing, which draws significant attention to materials with excellent chemical resistance properties. Since ULTRA SURFACE is unchanged by the alcohol, we can be confident that its beautiful appearance will last for a long time.

Features

Hard surface

ULTRA SURFACE is highly scratch-resistant. With 8H pencil hardness, the counter surface can resist scratches from everyday usage. Even when tableware and cutlery are placed directly on the counter, scratches will not be created. Moreover, it does not cause annoying high-pitched sounds like natural stone.

Impact resistance

The Charpy impact resistance value of Ultra Surface is high. Also, according to the steel-ball drop-test result, Ultra Surface impact resistance ability is several times higher than natural stones, ceramic plates, engineer stones (ES), and crystallized glass plates. Therefore, Ultra Surface is an exceptionally reliable material for kitchen counters.

Chemical resistance property

While both ULTRA SURFACE and engineering stones are quartz-containing materials, ULTRA SURFACE does not show as low alkali resistance as engineering stones. This property was verified with the household-bleach resistance experiments. In other words, our unique composite material technology has overcome most of the common weaknesses of artificial materials.

Heat resistance property

When heated, some engineering stones fade to different colors; however, ULTRA SURFACE demonstrates no changes in surface color and surface appearance. It is the result of our technological innovation.

Stain resistance property and cleanability

As a result of many years of technical innovation in composite materials, the stain resistance property of Ultra Surface, the most critical requirement for kitchen counter, is unmatched by any other counter materials. Ultra Surface has no fatal drawback. Also, thanks to its excellent cleanability, it is super easy to clean.

Long and wide counter size

From two super large sizes 1000mmx2800mm and 760mmx3100mm, we can design beautiful and seamless counters.

While in the case of engineering stones and natural stones, the sink has to be mounted at the site; in the case of our Ultra Surface, the sink is mounted into the counter at our processing plants beforehand. Therefore, the finished product is less likely to be damaged during transportation and installation.

Composition and physical properties

Ultra Surface is made of fine particles of quartz and highly purified crystals. The material structure is built with specialized polymers as the material matrix, glass fibers as reinforcing agents, gone through a unique kneading method to become a brand-new material with high- performance and high hardness.

Material property comparison with other materials

| Material Properties | Testing Method | Test result | |||||

|---|---|---|---|---|---|---|---|

| ultra surface | Engineered stone | Ceramic | Ceramic | ||||

| Company A | Company B | Company C | Company D | ||||

| Product thickness | 6mm | 12mm | 12mm | 8mm | 8mm | ||

| Density(g/cm3) | JIS K 6911 | 1.82 | 2.40 | 2.40 | 2.43 | 2.33 | |

| Flexural strength(MPa) | JIS K 6911 | 62.4 | 53.1 | 52.0 | 58.3 | 52.6 | |

| Flexural modulus(GPa) | JIS K 6911 | 12.2 | 36.9 | 34.9 | 50.8 | 38.4 | |

| Tensile strength(MPa) | JIS K 6911 | 24.7 | 22.5 | 18.4 | 14.2 | 9.2 | |

| Charpy impact test(kJ/m2) | JIS K 6911 | 3.63 | 1.92 | 1.83 | 1.55 | 2.51 | |

| Barcol hardness | JIS K 6911(934-1) | 72 | 83 | 87 | 93 | >100 | |

| Pencil hardness | JIS K 5400 | 8H | 9H | 9H | 9H | 9H | |

| Ball impact resistance test | maximum height at which the surface is not broken when dropping 1kg steel ball freely | no plywood backing | 60cm | 20cm | 20cm | <10cm | <10cm |

| 12mm plywood backing | 200cm | 90cm | 70cm | 10cm | 20cm | ||

| Boiling water resistance | samples are boiled under the condition of 92oC in 24hours, then changes in appearance are observed. | unchanged | unchanged | the black sample is whitened significantly, and the white sample is unchanged | unchanged | unchanged | |

Notes:The test results are recorded values and not guaranteed

STAIN RESISTANCE TEST DATA

| ultra surface | Company A | Company B | Company C | Company D | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Code | C101 | C200 | C202 | C300 | C302 | Engineered stone | Engineered stone | Ceramic | Ceramic | ||||||

| Color | white | grey | black | beige | brown | white | beige | dark brown | black | white brown | black | grey white | Grey + black & white | black | white |

| Coffee | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | △ |

| Soy sauce | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| Curry powder | ◎ | ◎ | ◎ | ◎ | ◎ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | △ |

| Bleach (household type) | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | × | × | × |

| Toilet Cleaner | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | ◎ |

| Hair dye | ⚠︎ | ⚠︎ | ◎ | ⚠︎ | ◎ | ⚠︎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | × |

| Ink | ○ | ○ | ◎ | ○ | ○ | ⚠︎ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | × |

| 5% Sodium hydroxide | ◎ | ◎ | ◎ | ◎ | ◎ | × | × | × | × | × | × | × | × | × | × |

| Oil-based marker | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | × |

| Water- based marker | ○ | ◎ | ◎ | ◎ | ◎ | ⚠︎ | ◎ | ◎ | ◎ | ⚠︎ | ◎ | ◎ | ◎ | 〇 | x |

Test method: Stains are dropped and adhered to the surface of the materials. After being left in contact for 24 hours, the surface is cleaned by removing the remaining stains and the stain-resistant properties are confirmed.

◎: Can be removed by wiping it with water.

○: Can be removed by wiping with neutral detergents.

△: Can be removed by lacquer thinner (acetone)

⚠︎: Can be removed with bleach (household type).

×: Irremovable

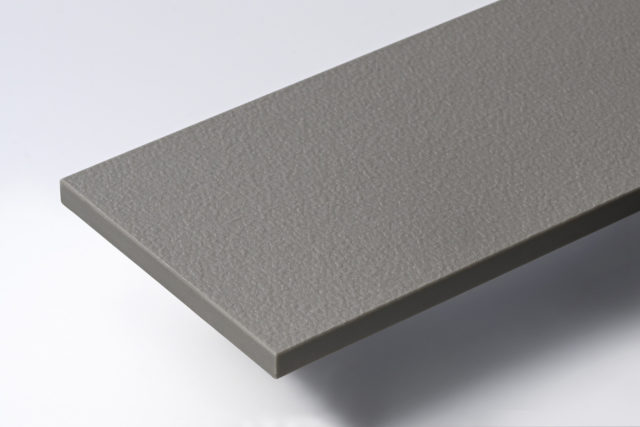

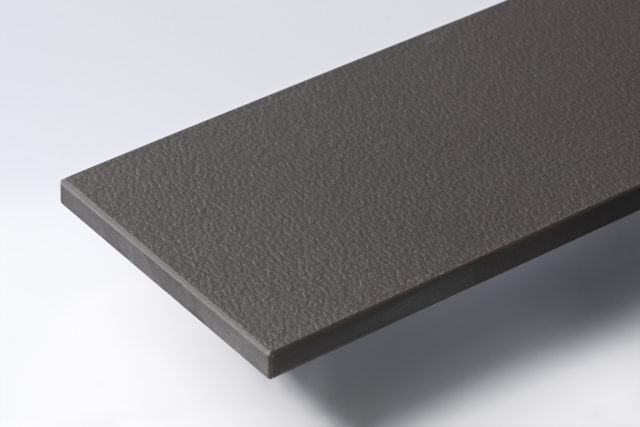

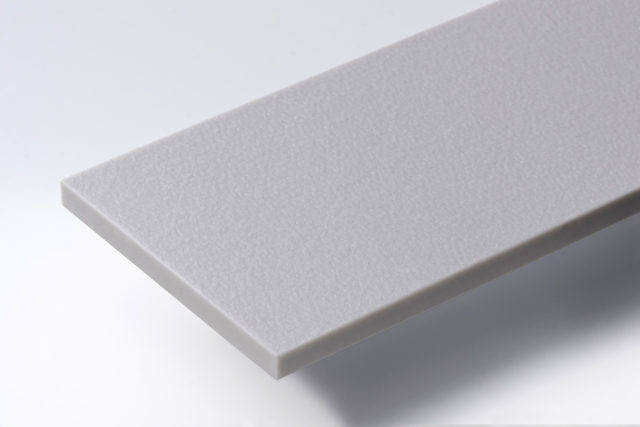

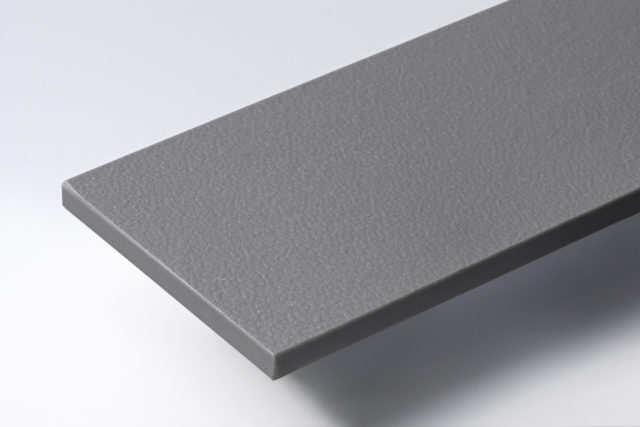

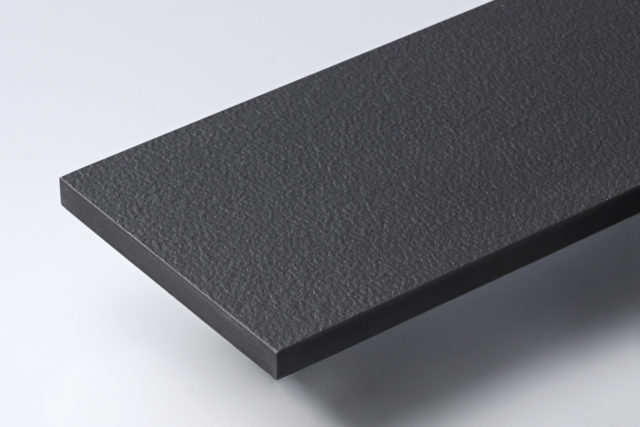

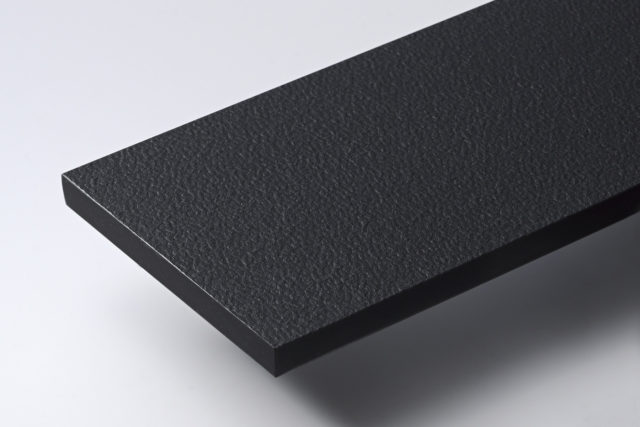

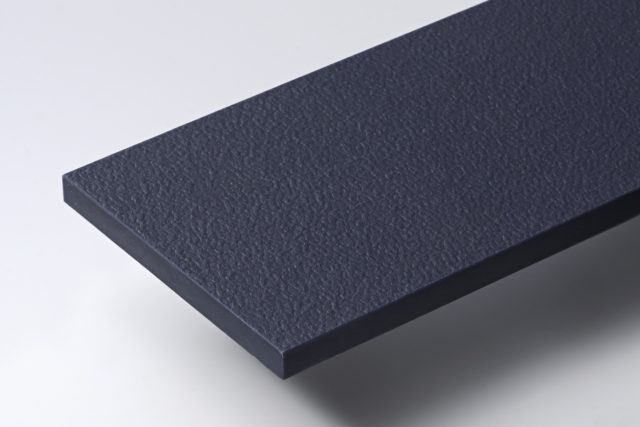

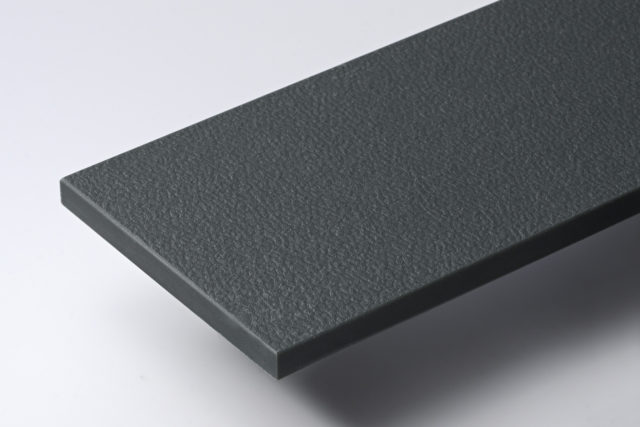

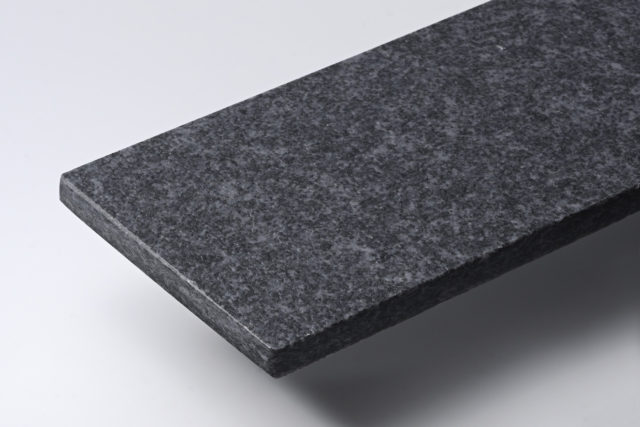

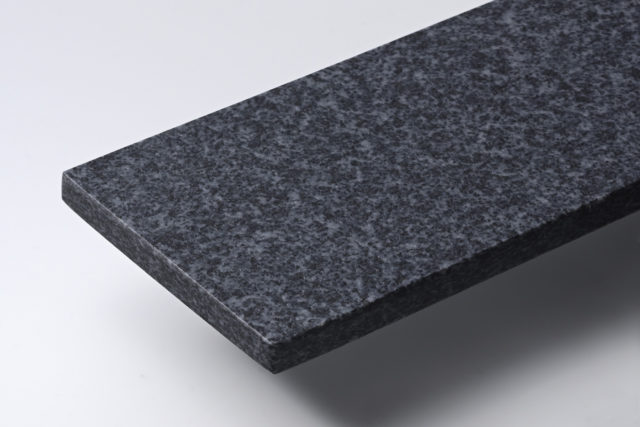

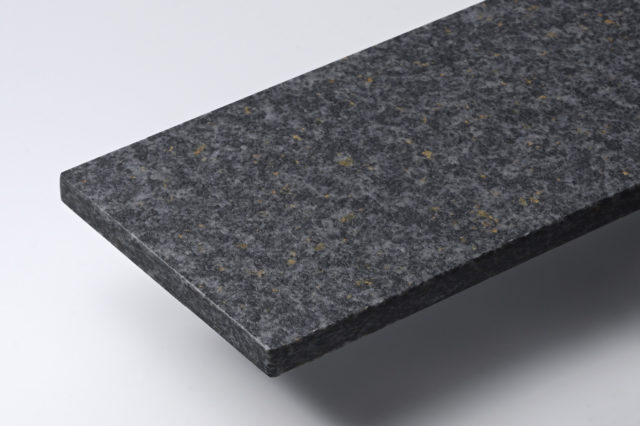

Product Image

NATURAL

DURARTE

Notes:Since the product contains a large amount of natural stone mineral, the color of the photos may be different from the actual one.