Introduction to BMC Artificial Marble

Artificial Marble material is widely-used for kitchens, bathroom counters, and other furniture counters. Even when materials are categorized as “Artificial Marble”; their properties are wildly different depending on their formulation, mixing methods, and molding techniques.

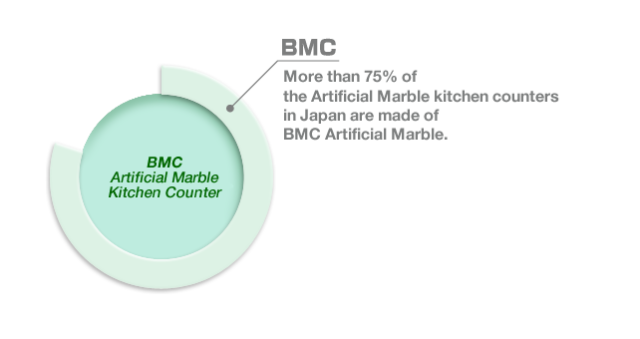

Approximate 40 years ago, Yoshimoto was the world’s first manufacturer who researched, developed and scaled up to large-scale the production of BMC Artificial Marble for kitchen counter, vanity counter, and washbasin. Since the products are molded at high temperature and high pressure, the product performance and property are superior to other artificial marbles. Thus, in Japan, BMC Artificial Marble occupies nearly 80% market share of artificial marble kitchen counters.

Due to focusing on high-performance, uses of specialized resins and glass fiber increase the material cost. However, by conducting the mass molding system, Yoshimoto has successfully reduced costs and stably supplied BMC Artificial Marble products to most major house makers and developers in Japan.

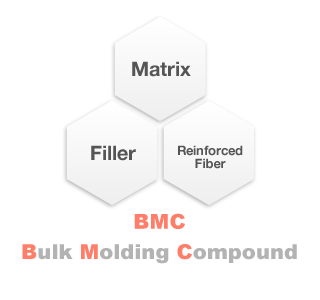

BMC (Bulk Molding Compound) is a thermoset composite material for mass molding processing. The material matrix, fillers, reinforcing fibers, and other materials are kneaded in a kneader until uniform. After that, the bulky mixtures are molded into different products with different shapes and sizes. The BMC’s most unique feature is its customization ability in terms of moldability and specific material performance properties.

Technical Uniqueness of BMC Artificial Marble

1. Strong heat and chemical resistance

Depending on applications, it is possible to customize heat resistance, chemical resistance, and scratch resistance by formulating specialized material matrices, fillers, and modifiers. For example, our Hyper Sink made of Crystal Surface material is the most scratch- resistance Artificial Marble sink (8H pencil hardness).

2. Thin but Strong

Since BMC material is built upon specialized polymer matrices, strengthened by fillers, and reinforced by glass fiber, the BMC Artificial Marble’s physical strength is significantly higher than conventional Artificial Marble.

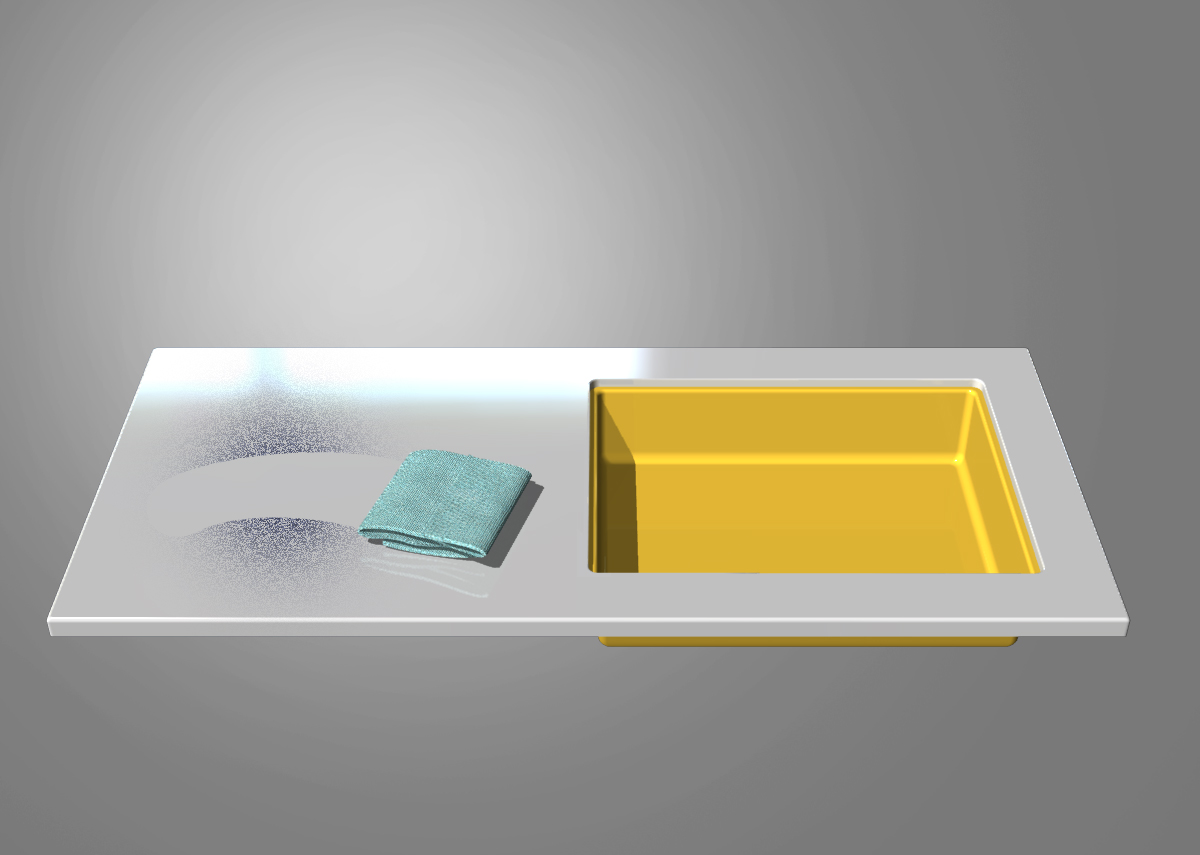

3. Hygienic and easy to clean

Greasy and persistent stains adhere to the product surface can be removed easily by detergent, cleaner, and solvent.

4. Outstanding dimensional stability

Since BMC Artificial Marble products are molded and hardened under high temperature and high pressure, they have super high dimensional stability. In other words, BMC is the ideal material for long counters such as kitchen and dining counters.

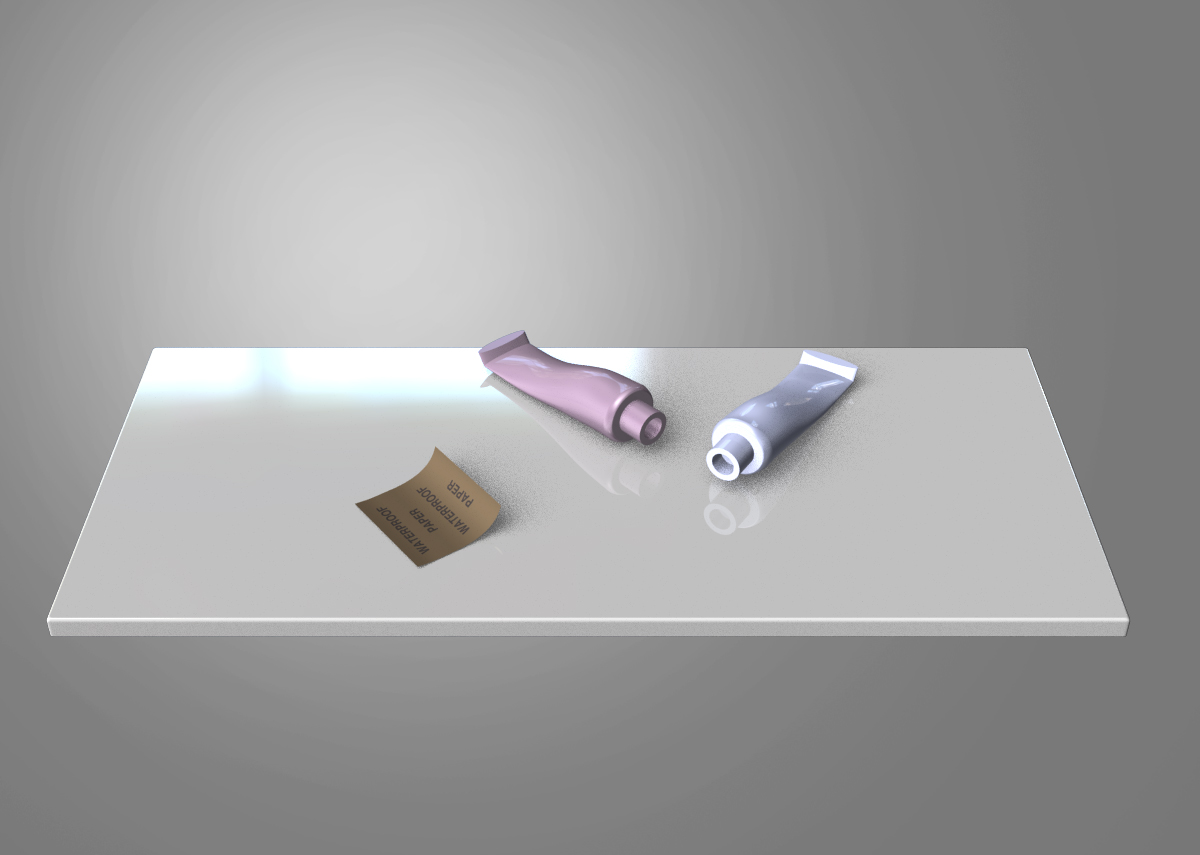

5. Easy maintenance

BMC is a solid material. While scratches can be repaired easily with sandpaper, more critical defects such as chips or cracks can be repaired with special repair agents.

BMC Artificial Marble Development and Manufacturing

1. Research & Development / Product Planning

From the world’s latest trends in material development, we plan and build exclusive material and products.

2. BMC Manufacturing

Developed from years of know-how and experience, efficient production systems and special formulation techniques of Yoshimoto’s BMC Artificial Marble are attracting attention from the world.

3. Press System

With Japan’s leading system of super-large press machines, Yoshimoto produces and supplies an unimaginably large amount of BMC Artificial Marble products to the market.

Artificial Marble Classification

The material generally called “Artificial Marble” is often referred to as two major polymer systems: polyester and acrylic. However, the material performance significantly differs due to numerous factors like types of material matrix, fillers, kneading technology, and molding method.

| Press Method | High Heat and Pressure Press Method | Casting Method | |||

|---|---|---|---|---|---|

| Material Classification | BMC (Bulk Molding Compound) | PMMA (Polymethyl methacrylate resin) | Unsaturated polyester | ||

| With gel coat layer | Without gel coat layer | ||||

| Raw Material Characteristics | BMC is a composite material made of polymer matrices, fillers, and reinforcing agents. It is possible to build the material matrix from numerous acrylic and unsaturated polyester systems. Also, the material properties can be tailor-designed by reinforcing agents and specialized fillers. | PMMA/ MMA monomer/ filler | With a decorative layer (resin) and a base layer Notes:The filler used for the base layer is mainly calcium carbonate | Without a decorative layer (a base layer only) | |

| Material Properties ◎ Excellent 〇 Good △ Fair ✕ Poor | Dimensional stability | ◎ | ✕ | ✕ | ✕ |

| Impact resistance | ◎ | 〇 ~ △ | ✕ | ✕ | |

| Chemical resistance | ◎ | ✕ | 〇 ~ △ | ✕ | |

| Stain resistance | 〇 | △ | 〇 | ✕ | |

| Heat resistance | ◎ | ✕ | ✕ | ✕ | |

| UV resistance | 〇 | ◎ | ✕ | ✕ | |

| Remarks | 1. Excellent resistance to organic solvents, acids, alkalis, and chemicals 2. Occupy more than 75% market share of domestic artificial marble kitchen counter | 1. Absorb ethanol and organic solvents, lead to surface damages in a short time | |||